It provides a comprehensive view of production costs, crucial for pricing, budgeting, https://www.pavillonmaya.com/5-best-airbnb-accounting-software-tools-for-2024/ and financial analysis. COGM is thereby the dollar amount of the total costs incurred in the process of manufacturing products. The Cost of Goods Manufactured (COGM) represents the total costs incurred in the process of converting raw material into finished goods. By simplifying the evaluation process, it aids businesses in tracking production expenses, preparing financial statements, and assessing operational efficiency.

Duct Bend Area Calculator

The Cost of Goods Manufactured (COGM) is a key accounting concept that encompasses all the expenses incurred in the production process to create finished goods ready for sale. COGM is calculated by adding up these costs and adjusting for the beginning and ending work in process inventory. This metric is essential for businesses to assess the total cost of production, determine product pricing, evaluate cost efficiency, and analyze overall profitability. Once the total manufacturing costs incurred are calculated, work-in-process (WIP) inventory must be incorporated to determine the Cost of Goods Manufactured. These products have consumed direct materials, direct labor, and manufacturing overhead but are not yet ready for sale.

COGM Calculator

This tool is ideal for manufacturers, finance teams, internal auditors, and students learning about cost accounting who want to understand production costs and improve profitability. WIP represents any partially-complete inventory that is not yet marketable, i.e. they have not yet become finished products ready to be sold to customers. Enter the cost of materials, labor, manufacturing overhead, beginning work in process inventory, and ending work in process inventory into the calculator to determine the cost of goods manufactured. The calculator also distinguishes between COGM and cost of goods sold (COGS), enabling a clear understanding of the total expenses involved in manufacturing versus those incurred after production. Ultimately, the Cost of Goods Manufactured Calculator is a vital resource for streamlining production cost management. It empowers businesses to make informed decisions, optimize operational processes, and maintain financial transparency effectively.

Company

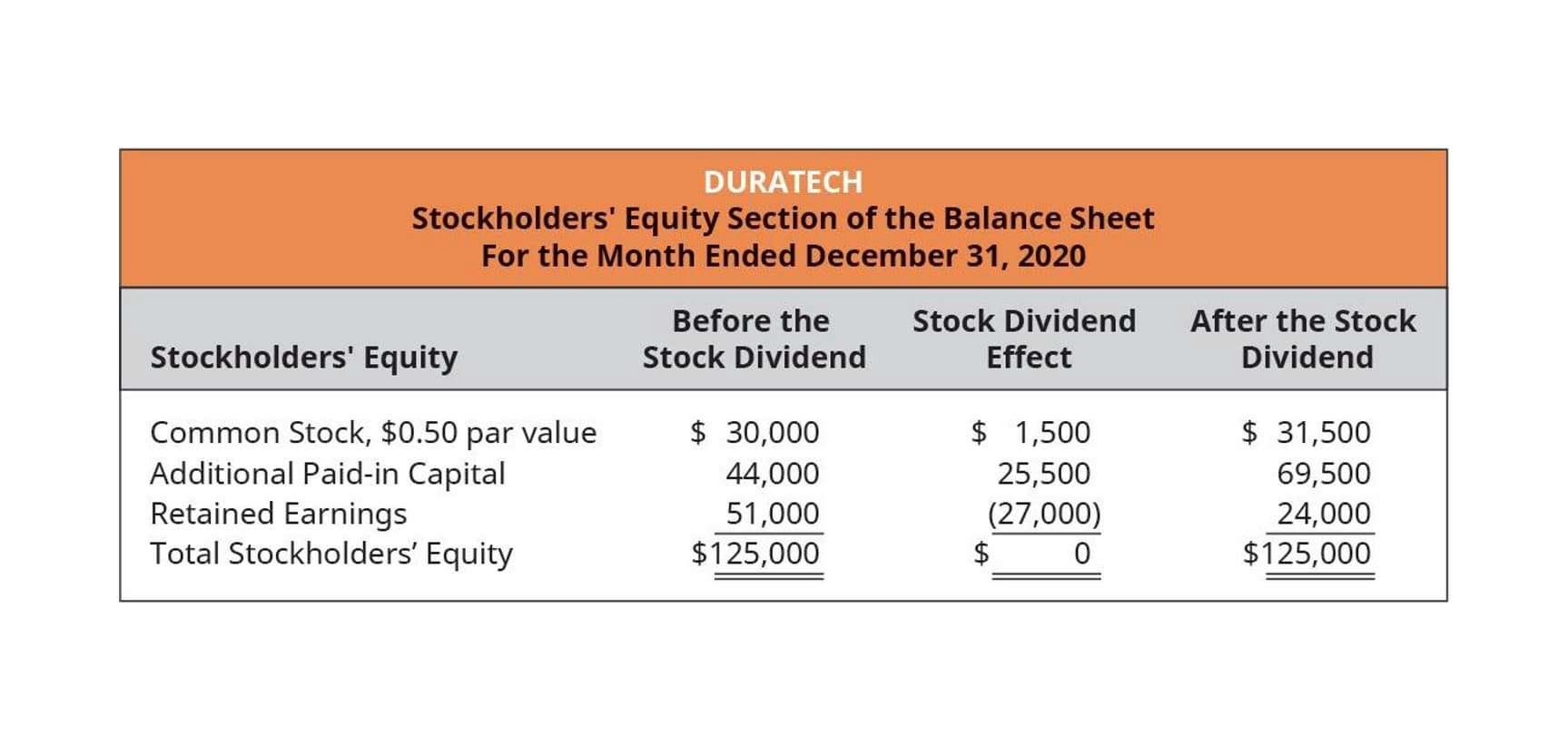

This consolidated calculation provides the final assets = liabilities + equity figure for the cost of products completed and transferred to finished goods inventory during the period. It integrates the consumption of materials, the application of labor, and the allocation of overhead, adjusted for inventory in various stages of completion. Subtracting the value of raw materials remaining at the end of the period yields the cost of materials consumed in the production process. For example, if a company started with $10,000 in raw materials, purchased $5,000 more, and ended with $3,000, the direct materials used would be $12,000. This method ensures that only materials transformed into products are accounted for in the current period’s production costs. Manufacturing costs refer to any costs incurred during the process of manufacturing a finished product and include the 1) cost of raw materials, 2) direct labor, and 3) overhead costs.

Identifying the Cost Components

This figure represents the value of raw materials actually put into production, not merely purchased. An accurate calculation of direct materials used is important because it directly impacts the total manufacturing costs. The final step in determining the Cost of Goods Manufactured involves assembling all previously calculated components cost of goods manufactured calculator into a statement.

- To use the calculator, input key values such as direct materials, direct labor, and manufacturing overheads, along with the beginning and ending work-in-process inventory.

- If we enter those inputs into our WIP formula, we arrive at $44 million as the cost of goods manufactured (COGM).

- This amount signifies the entire cost input into the manufacturing process before considering the stage of completion of the goods.

- This consolidated calculation provides the final figure for the cost of products completed and transferred to finished goods inventory during the period.

- By simplifying the evaluation process, it aids businesses in tracking production expenses, preparing financial statements, and assessing operational efficiency.

- It empowers businesses to make informed decisions, optimize operational processes, and maintain financial transparency effectively.

Evaporation Rate (Water) Calculator Water Evaporation Calculator

- The beginning work in progress (WIP) inventory is the ending WIP balance from the prior accounting period, i.e. the closing carrying balance is carried forward as the beginning balance for the next period.

- For instance, the wood used by a furniture manufacturer or the fabric for clothing are considered direct materials.

- The Cost of Goods Manufactured (COGM) Calculator determines the total production cost of goods completed during a specific period.

- After identifying direct materials, the next step in calculating COGM involves determining the cost of direct materials consumed during the production period.

- Manufacturing costs refer to any costs incurred during the process of manufacturing a finished product and include the 1) cost of raw materials, 2) direct labor, and 3) overhead costs.

Effortlessly calculate your Cost of Goods Manufactured (COGM) with our user-friendly online calculator! This essential tool empowers manufacturers of all sizes to gain valuable insights into production costs, optimize pricing strategies, and make data-driven business decisions. To use the calculator, input key values such as direct materials, direct labor, and manufacturing overheads, along with the beginning and ending work-in-process inventory. Conversely, ending WIP inventory is subtracted because these are costs incurred in the current period for products still incomplete and to be finished in a future period. Excluding these costs from the current COGM ensures that the calculation only reflects expenses for goods fully completed during the reporting period. This adjustment provides a measure of the cost of goods ready for transfer to finished goods inventory.

- The calculator also distinguishes between COGM and cost of goods sold (COGS), enabling a clear understanding of the total expenses involved in manufacturing versus those incurred after production.

- This tool ensures accurate calculations by allowing users to input data for each component and dynamically computes the COGM.

- For example, if a company started with $10,000 in raw materials, purchased $5,000 more, and ended with $3,000, the direct materials used would be $12,000.

- It integrates the consumption of materials, the application of labor, and the allocation of overhead, adjusted for inventory in various stages of completion.

- Effortlessly calculate your Cost of Goods Manufactured (COGM) with our user-friendly online calculator!

COGM Definition

The beginning work in progress (WIP) inventory is the ending WIP balance from the prior accounting period, i.e. the closing carrying balance is carried forward as the beginning balance for the next period. Before we delve into the COGM formula, reference the formula below that calculates a company’s end-of-period work in progress (WIP) balance. This COGM calculator is an invaluable tool for any manufacturer seeking to streamline cost analysis and make sound business decisions. If we enter those inputs into our WIP formula, we arrive at $44 million as the cost of goods manufactured (COGM). The beginning work in progress (WIP) inventory balance for 2021 will be assumed to be $20 million, which was the ending WIP inventory balance from 2020.

Once the manufacturing costs have been added to the beginning WIP inventory, the remaining step is to deduct the ending WIP inventory balance. The COGM formula starts with the beginning-of-period work in progress inventory (WIP), adds manufacturing costs, and subtracts the end-of-period WIP inventory balance. Integrate it into your workflow and reap the benefits of having a clear picture of your production costs. COGM is assigned to units in production and is inclusive of WIP and finished goods not yet sold, whereas COGS is only recognized when the inventory in question is actually sold to a customer. To calculate the costs of goods manufactured, simply sum the material, labor, and overhead costs, add in the beginning work in progress inventory, then subtract the engine work in progress inventory. For example, manufacturers can utilize this tool to format COGM statements, solve accounting problems, and practice scenarios involving cost analysis.